home > Management consulting > Operational Excellence > Reduce costs and increase efficiency >

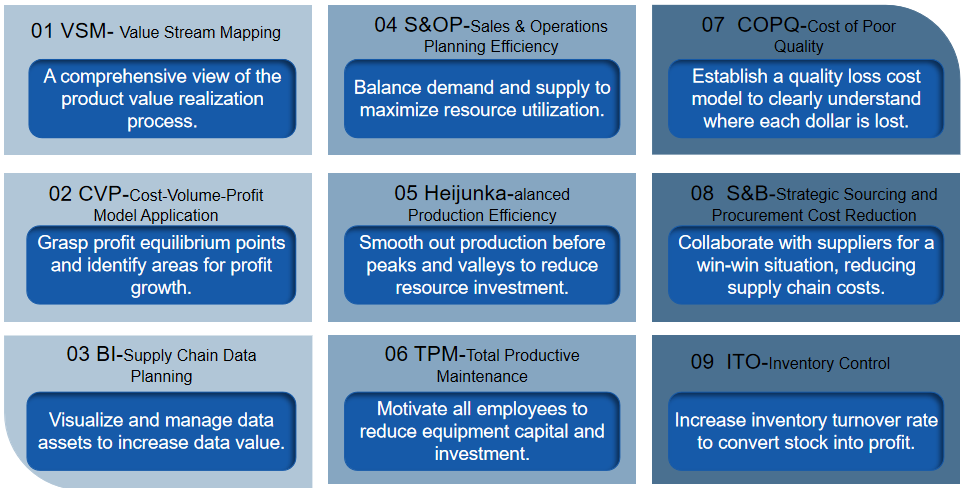

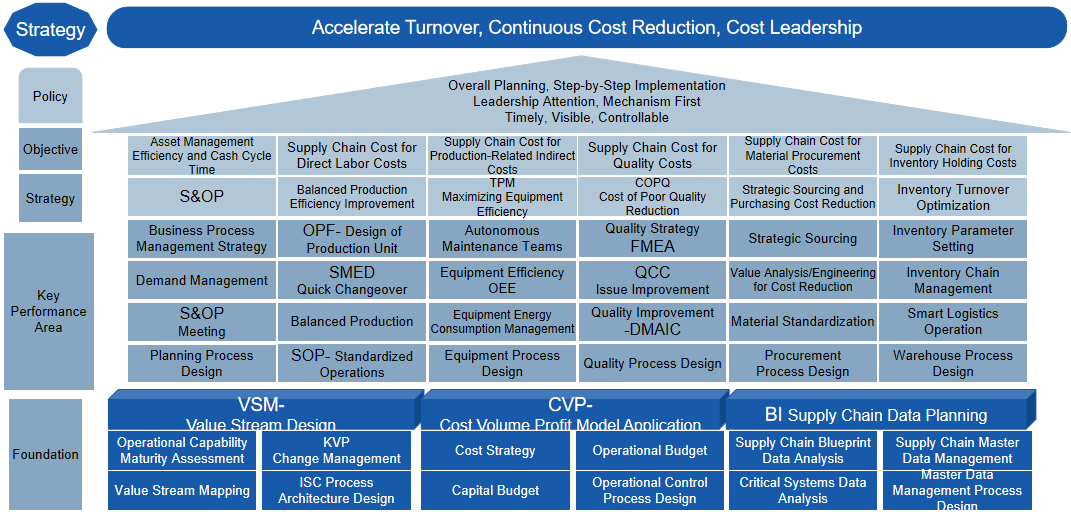

Realscheme's "Cost Reduction and Efficiency Improvement Solutions" focus on integrating the entire ISC (Integrated Supply Chain) process, from demand to delivery, within manufacturing enterprises. By applying methodologies such as value stream mapping, CVP (Cost-Volume-Profit) models, BI (Business Intelligence) for supply chain data planning, S&OP for production and sales coordination, Heijunka for balanced production, TPM for equipment optimization, COPQ for quality cost reduction, S&B for strategic sourcing and procurement cost reduction, and ITO for inventory control, Realscheme provides top-level planning and implementation pathways. The goal is to identify and overcome system bottlenecks, improving overall supply chain performance and helping businesses enhance production efficiency and rapidly improve operational performance.

Reduce costs and increase efficiency, nine incur profits

Technical Method

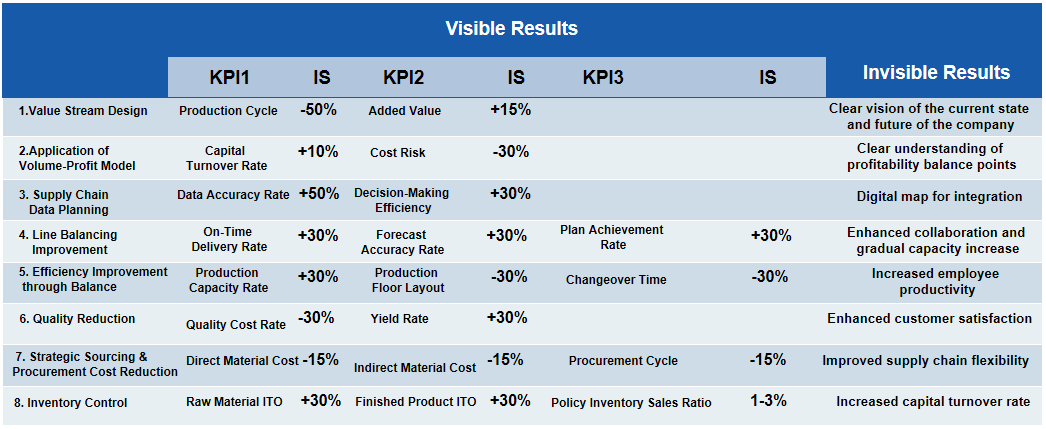

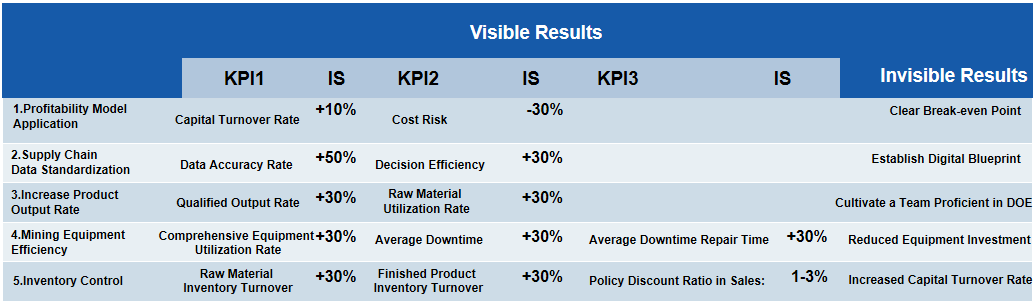

Expected Outcomes

Three-Year Goals for Cost Reduction and Efficiency Improvement in Discrete Manufacturing Enterprises:

Expected three-year results of cost reduction and efficiency improvement for process oriented enterprises

This is a promotional slogan