home > Management consulting > New Quality Productivity > Timely manufacturing and agile delivery >

Realscheme begins with lean production and smart manufacturing, applying key data systems to describe, evaluate, and manage strategy. By introducing lean production methodologies, Realscheme drives operational management system transformation, helping enterprises evolve from standardization and lean practices to digital and intelligent systems. Strategically planning aroundtime Realscheme identifies and overcomes system bottlenecks to improve overall supply chain performance, enabling rapid operational improvements and sustainable growth. Key tasks and deliverables of **Realscheme’s Excellence in Operations** include: - **Intelligent Factory Planning** - **Just-in-Time Manufacturing and Agile Delivery** - **Development of Key Data Systems** - **Total Productive Maintenance (TPM)**

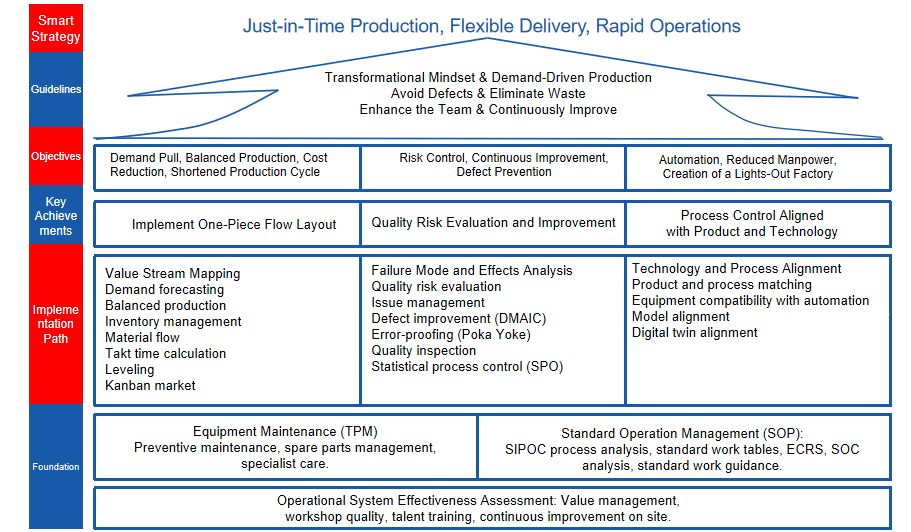

Realscheme integrates demand forecasting models, completing PQ/PR analysis and one-piece flow unit production layouts. It clarifies corporate product planning strategies, identifies automation upgrade needs, standardizes hardware and software requirements, aligns internal and external logistics optimization solutions, optimizes production scheduling, introduces quick changeover techniques, and implements flexible production. The key elements of Realscheme's "Just-in-Time Manufacturing and Agile Delivery Consulting" include:

• Operational Maturity Assessment: Value Chain Management + Operational Excellence + Built-in Quality + Equipment Management + Process Management + Lean Talent + Lean Teams + Lean Worksites + Continuous Improvement.

• One-Piece Flow Production Layout: Demand-driven production, balanced production, cost reduction, compressed production cycles.

• Quality Risk Assessment and Improvement: Risk control, continuous improvement, defect prevention.

• Process Control Matching Product Processes: Automation, reduced labor, establishing lights-out factories.

• Equipment Maintenance (TPM): Initial equipment management, six-source equipment management, autonomous maintenance, professional maintenance.

• Standard Operations Management (SOP): SIPOC process analysis, standardized operation sheets, ECRS (Eliminate, Combine, Rearrange, Simplify), SOC (Standard Operation Check) work observation sheets, SOP standard operation instructions.

This is a promotional slogan