home > Management consulting > New Quality Productivity > Smart Factory Planning >

Realscheme approaches intelligent manufacturing from the perspectives of "Lean Production" and "Smart Manufacturing", using key data systems to describe, evaluate, and manage strategy. Realscheme implements lean production methodologies to drive operational management transformation, helping enterprises evolve from standardization and lean practices to digital and intelligent systems. By strategically planning around time, Realscheme identifies and overcomes systemic bottlenecks to improve overall performance in supply chain systems, rapidly improving operational efficiency and ensuring sustainable growth. Key tasks and deliverables of "Realscheme’s Excellence in Operations" include: - Intelligent Factory Planning - Just-in-Time Manufacturing and Agile Delivery - Development of Key Data Systems - Total Productive Maintenance (TPM)

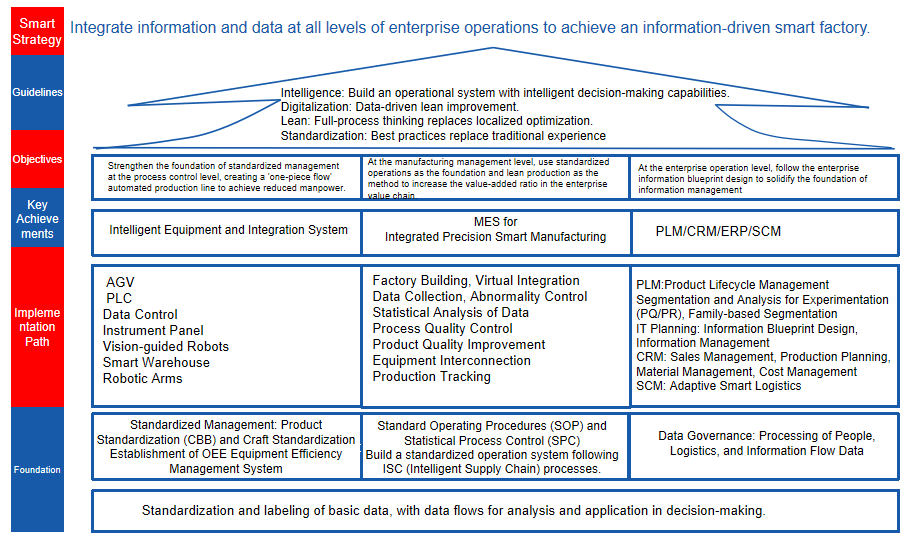

Realscheme constructs an ''Intelligent Manufacturing Capability Assessment Model'' by utilizing ''Value Stream Mapping (VSM)'' tools to diagnose all sub-domains of the manufacturing enterprise's processes. This results in a strategic execution capability report. Realscheme helps enterprises extract a development blueprint from lean production to intelligent manufacturing, setting progressive goals for process control, manufacturing management, and overall enterprise operations while clarifying the path for implementing intelligent strategies. Key elements of Realscheme's ''Intelligent Factory Planning Consulting'' include:

• Intelligent Manufacturing Capability Assessment: Personnel + Technology + Resources + Design + Production + Logistics + Sales + Service.

• Process Control Layer: Strengthen the foundation of standardized management, create automated "one-piece flow" production lines, and reduce the need for human intervention.

• Manufacturing Management Layer: Based on standardized operations and lean production, improve the value-added ratio in the enterprise's value chain.

• Enterprise Operation Layer: Design and implement an enterprise information blueprint to solidify the foundation of information management.

• Standard Management: Standardize product management (CBB), manage technical process parameters, and establish an OEE (Overall Equipment Effectiveness) management system (TPM).

• Standard Operations: Integrate ISC (Integrated Supply Chain) processes end-to-end, establish a standardized operations management system (SOP), and apply process mapping technologies (SPC).

• Data Governance: Streamline product flow, logistics, and information flow to form standardized data and regulate data circulation and decision-making applications.

This is a promotional slogan