home > Management consulting > Digital consulting > Digital Factory >

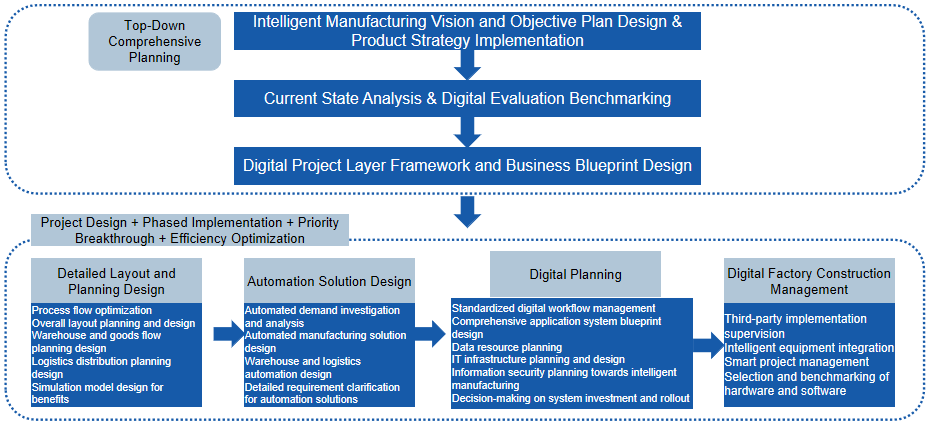

Realscheme’s ''Digital Factory Planning Consulting'' combines industry insights with product characteristics to construct the basic framework of a digital factory for manufacturing enterprises. It is dedicated to helping companies achieve intelligent manufacturing, providing neutral third-party digital factory planning consulting and implementation supervision services. Realscheme supports enterprises in building actionable digital factories, particularly for new factory construction, upgrades, and relocations of existing factories. The top-level design solutions are tailored to the enterprise’s current stage and future development goals, considering production layout characteristics, product process features, current conditions, and strategic intent.

Realscheme provides intelligent manufacturing services to manufacturing enterprises, ranging from strategic execution to implementation, digital standardization of process analysis and optimization, lean layout optimization design, digital factory integration architecture design, issue analysis of current factory conditions, and training. The key tasks and deliverables of Realscheme's digital factory planning consulting include:

• Production Line and Logistics Layout | • Intelligent Manufacturing Maturity Assessment and Diagnosis | • Digital Factory Construction Planning (EPC General Contracting) |

• HSE (Health, Safety, and Environment) Planning and Training | • Long-Term Factory Layout Planning | • Digital Factory Project Supervision |

| • Lean Training | • Production Line Design | • Digital Factory Implementation Third-Party Supervision |

| • Lean Manufacturing Planning | • ...... | • ...... |

At the beginning of digital factory project construction, Realscheme considers key business aspects such as planning, production, quality, logistics, equipment, and processes to develop a unified top-level business design for the digital factory. The implementation is carried out in phases based on difficulty, urgency, and business relevance to minimize the impact of new systems and business processes on operational departments. The solution design ensures a closed-loop process, establishing a model where back-end operations pull front-end activities, and front-end operations drive back-end execution. This supports manufacturing enterprises in transitioning from transparency in manufacturing processes to digitalization and ultimately intelligent manufacturing.

This is a promotional slogan